|

|

|

|||||

|

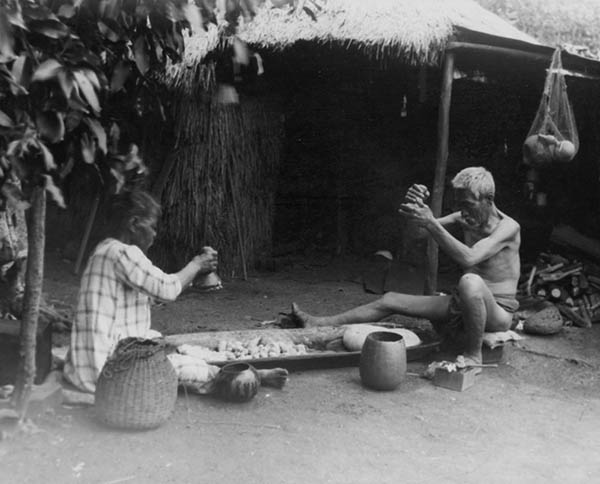

Making Poi:

“We used to have to help my grandfather peel all the kalo and kalopa‘a and ku‘i so that we would have poi,” Emalia recalls. “My mother used to pound poi with a certain rhythm and a certain mele that she used to sing. Stone pounder. We had quite a few of those poi pounders and boards, the papa. A lot of that rotted after awhile, but we still have some of those poi ponders. Now my nephews, they all know how to ku‘i kalo, so they know how to feed their families in case.” “My family has a certified poi mill on our farm in Waiahole,” says Nick Reppun. “We’ve got a big steamer that can actually hold up to 1,000 pounds of raw taro. Usually, we’ll steam the taro the night before, and then it just sits in the steamer. Cook it for several hours, and then the next morning we’ll come in, and all the cooked taro gets dumped into a big, big trough."

|

|

|

|

“That trough has a raised grate on the bottom. And we fill that trough with water, and that cools down the taro. But then also we use that water and we do a rough clean. We call it a rough clean to take in a majority of the skin off, and that’s just done by hand—rubbing the taro, the skin usually. Ideally, the skin just slides right off. Sometimes if the taro is a little dry, it’ll be kind of sticky, just scrape it a little bit. “But rough-clean it, drain the water out, rinse it all down, clean all the debris off of it (little leftover pieces of skin and stuff). Hose it down and then we do a fine clean, which is coming back through and using spoons to scrape the surface of the taro, checking for any little root eyes—that would be a little hard thing—or other little imperfections that might come, like little pieces of rot or something like that that didn’t get trimmed off when we were pulling the taro."

|

|

|

|

|

|

“And then I usually we do a quality-control check where we cut it all into smaller pieces that are manageable for the mill. But has the dual-purpose of breaking it down to an appropriate size to mill it, and then also sometimes even though the outside looks fine, there’s something weird going on in the middle. “Then it gets run through the mill. It’s an old mill. It’s basically what you would commonly see as a grain mill. But it uses a screw that pushes the material in. It pushes the chunks of taro into what are called burred plates. There’s one plate that’s stationary, and then the other one rotates. They’ve got these little grooves on the outside edge, maybe an eighth of an inch deep. And then in a regular grain mill, you would run from an eighth of an inch to a sixteenth of an inch. It’s like a little wedge that forces materials smaller and smaller."

|

|

|

|

“But for the poi mill, you grind the outside edge of the plate to almost totally smooth. And so you’re getting a finer particle size out of it. It squeezes through that, and then it goes from the mill into a big bowl. Then we mix some water to bring it to the right consistency. And then from there, we bag it. “We tend to mix it well. The amount of water that you add, that also depends on, again, the starch content. Less starchy taro will hold less water. If it’s really starchy, you can add more water to get to the same consistency. We try to keep our poi relatively thick. That’s the way that I learned. Some people will take our bag and squeeze it out into a bowl, mix it down a little bit more. I just eat it straight. I like nice, thick poi, but I guess that’s a personal preference. But I think for the most part, people would mix a little bit of water."

|

|

|

|

“We’re hoping to build our own permanent poi factory structure here. We’d like to get it done this year. We’ll probably need multiple poi mills within this area. In that historic photograph, the 1928 one, I think there are four different poi mill sites. I mean, you’ve got 200-plus acres of taro production. There’s no way one mill could handle all of that. You’d be running that 24/7 probably. It’d make sense to have one for that area, one for that area. It’s a big property.” |

|

|||||

|

|||||