|

|

|

September 24, 2013

In their great work Canoes of Oceania, a landmark in research of Pacific Islander canoes, published in 1936, authors A. C. Haddon and James Hornell state that their study began with a particular focus on how different island cultures attached the outriggers to their canoes. Clearly this is a distinguishing feature across Oceania—as characteristic, if not more so, than the shapes of the canoes themselves—and I have seen quite a variety in my own limited travels. For Hawaiians, it was simple: The booms (‘iako) curve down from the gunwales of the canoe and are pegged, then lashed, directly to a banana-shaped outrigger (ama). But elsewhere, it can get very complicated, and for the Melanesia design that I am building, it’s one of these tricky rigs. But first, we have to get all the parts together and hewn into shape.  Manu extending upward on the back end of the ‘Auhou, NMAI’s Hawaiian canoe. Protruding below it is the notched extension where ropes would have been attached to bring the rough-hewn hull out of the forest.

Manu extending upward on the back end of the ‘Auhou, NMAI’s Hawaiian canoe. Protruding below it is the notched extension where ropes would have been attached to bring the rough-hewn hull out of the forest.While koa was the tree of choice for canoe hulls, lighter woods were preferred for the rest of the parts. Koa is a very stiff and dense wood and therefore very, very heavy. Jay Dowsett and Tay Perry, who build and refurbish canoes in Honolulu today, note that in the old days, a lot of those canoe hulls were an inch-and-a-half or two inches thick just to keep them rugged. That also made them very heavy. Hawaiian canoes have separate gunwale pieces attached (by stitch and glue) atop the hull, culminating in lovely upright prows and sterns called manu, a hallmark of Hawaiian canoe design. These areas, which are repeatedly struck by the paddles, would be made of ‘ahakea—a fairly light wood, but very stiff. It’s comparable to ash, which is not particularly heavy for its volume, but is also very stiff. ‘Ahakea wood is a dull orange-brown and when rubbed with kukui oil becomes a beautiful dark golden yellow. For the booms (‘iako) that connect the outrigger to the hull, hau was an excellent choice. A member of the hibiscus family, hau grows in low, tumbling forests of curved limbs. Pick two that have the right curve and you’re set. And the wood is light and peels easily. In fact, the bark makes a decent rope. The outrigger, or ama, would be made of wiliwili. This lovely tall tree produces red seeds, and red being the color of chiefliness, these seeds are equated with the blood of the chiefs. Wiliwili is also very light, which is what you want your float to be. Its purpose, you see, is to float. Here in the mid-Atlantic area, there’s a dearth of ‘ahakea, hau, and wiliwili. But, as with ash and ‘ahakea, we can look for trees with comparable qualities. Now I knew more about trees in New England, where I spent a lot of my youth, than I did about the mid-Atlantic. Some of these trees around here are completely unfamiliar to me. And I’m not a woodworker to begin with. And in New England, firewood was the big issue, so I became familiar with wood that split well and burned hot. Period. Now I need to know much more about the qualities of different woods. Fortunately, in the 21st century, there is the online Wood Database. This excellent free resource is quite extensive (though Hawaiian woods are strangely absent) and gives a great deal of information about the qualities of different woods. Among these, the important ones for me are dry weight, strength, shrinkage, workability, and perishability. I spent a lot of time going back and forth between this website and the State of Maryland’s Maryland Trees database, looking at what types of wood are available in this area. Lightness, for the ‘iako and the ‘ama, was a problem. The trees that are light are often also highly perishable, or just plain hard to find. Cedar, ash, and white pine aren’t common around my area—at least, not that I could find. Which brings us to another problem: If you live in the city, where do you find trees to cut? Well, there are four solutions. First, make friends with a logger or arborist who cuts trees for a living. Some of them stock up on the wood they cut, because they or their friends or relatives are woodworkers, too. Second, go directly to large private landowners who have some good-looking trees for your purposes, and see if they will let you cut them. Third is tree falls from storms. I have harvested a few pieces from these. Finally, you can be sneaky. After all, there are a lot of trees in my area—along the sides of highways or in highway medians, or the fringes of parks and streams, and so forth: no-man’s lands, in other words. That doesn’t make cutting trees there legal, and the fines can be up to $1000. I won’t reveal which option I used, but I will say that the trees that I cut were all, with one exception, standing dead—they were not green anymore, but they weren’t starting to rot, either. Okay, one of them could have been a little fresher. And the type I went for was Virginia pine, not a species with which I was previously familiar. First I cut a big log for the ama. It was a 40-foot tree, clearly dead in the last season, and with my folding handsaw, felling it was quite a chore. I cut the log longer than it needed to be, just in case. It may have been dead, but it was still mighty heavy. I propped one end on the back of my car roof, atop an old blanket, and slid it up on top of the car. Two straps, two ropes, and away I went, the happy owner of a beautiful pine log.  The first log I cut for my ama (which after all the work of harvesting and getting it home, turned out to be too heavy a type of pine). and two logs for ‘iako.

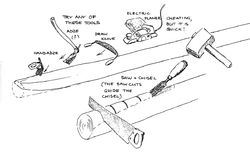

The only problem was that I had not read canoe-building the directions carefully. They say the dry weight of the wood for the ama should be about 26 pounds per cubic foot, and no more than 30. Virginia pine is 32 (oak, by comparison, is 42 or more). Back to the databases for another search. The only readily available local wood with a dry weight under 30 pounds is tulip poplar, which is plentiful, but perishable. So for this, I borrowed a friend and his chainsaw and we cut a live tree (after the appropriate propitiation of its spirit and thanks for its life). This totally green log would become my ama. For the booms, however, I went back to Virginia pine: light, reasonably straight, tough, and a bit more water-resistant. The only problem with it, as I quickly found out, is that it’s knotty. That makes shaping it down to size more difficult. The last wood needed is a series of sticks—four per boom, each about two feet long—that connect the ‘iako to the ama. This is not a Hawaiian design at all, as you will see. Here I lucked out. An area in a nearby streamside park had been cleared around some power lines, and a lot of young trees of the right diameter were already lying there cut. The process of turning these raw logs and cut saplings into shaped parts was far more laborious than the making of the hull. At the same time, here is where I really got into canoe carving—using bladed instruments to shape the wood. My primary tools were the drawknife (a blade with two handles, mine an antique), a hammer with large chisel, a plane, and a rasp.

The draw knife was good for removing bark and roughly taking each log down to the shape and diameter I needed. The hammer and chisel I used to cut out the knots in the Virginia pine and to shape the ends of the ama. The plane helped straighten out uneven areas more finely, and the rasp took care of the minor bumps, knotty areas, and general smoothing. Of course, I finished things off with the miraculous random orbital sander.

Now although the logs for the booms were as straight as I could get them, they still had curves to them. Carving them down to two inches in diameter from around three-and-a-half to four inches—well, yes, it’s a lot of extra work, but it gave me the opportunity to take some of those curves down and make the pieces straighter overall. So after divoting out the knots, I used the drawknife to make the first hard pass, removing the bark and taking off thick strips of wood. Have I mentioned that this took a lot of effort? I wondered if our ancestors had to work this hard, or whether there was some Zen of using this tool that I wasn’t getting. With that in mind, I did get better at it. I then used the plane to fine-tune the major work as much as possible, and used the rasp on the ridges and on the lumpy areas around the knots. The two tools worked very well at taking the wood down to a reasonably smooth contour. Top: All the carving is done, but the boom still looks pretty rough. Above: Nice and smooth—if not perfectly straight—after sanding. Right: To steady the log while I worked, I set up two bench clamps at the end of my long table and clamped a large C-clamp into them to hold the extended end of the log (cut off afterwards). You can see how much I took off of this log. The carved portion is not centered on the raw end; that was to take out some of the curve.The ama (float) was a different story. To begin with, the log was green. First thing I did was to take the bark off so it would begin to dry better. Lo and behold, tulip poplar is one of those tree species where the bark just peels right off! What a bonus! This log, again, was not perfectly straight. It had a curve on one end that I intended to use for the bow end, but side-to-side it had some issues as well. These too I tried to minimize as I took the log down to its final size. Mostly this log was to stay pretty round, though flattened a bit on the top. The ends, however, were to be tapered down to points. I decided to do the first end with just the hammer and chisel. By this point I was feeling pretty handy with these tools, and they are not too dissimilar from the adze of old—except that they are two separate pieces and the adze is one combined tool. Using the hammer and chisel, I felt, gave me much more precision and control, and reminded me of stone carvers I had seen in my youth. I felt like an artist at last. Artistic as the work might have been, it took a long time and a lot of careful eyeing to get the end of the log into the right shape. So to do the other end, I used a technique suggested in the instructions: Make sawcuts of increasing depth, and then chisel these off. Wow, this took much less time. The wood came off in huge chunks, and in half an hour I had done what took me perhaps two days on the firstend.

Mind you, I was doing this work in Baltimore in July, when it’s 95 degrees outside and often humid. I moved my work to an old picnic table in the shade and spend days shaping this thing, then leaving it in the sun to dry some more. In the end, I not only had a log that I can lift—at first, it was so green and full of water I had to drag it—but an outrigger that, after sanding, looks pretty good. It is already showing some cracks, but I’m not worried about that, because now I know about filleting. Next year when the log is totally cured, I'll fill those cracks and waterproof the float. For now, I’m just going to use it as soon as everything else is done. And I am getting into the final stretch.

—RDK Herman |

||

|

||

|

||

Copyright 2016, Pacific Worlds & Associates |